Clean Room Ancillaries

Clean Room Ancillaries Specification

- Temperature

- 10C to 45C operating range

- Application

- Pharmaceutical, Electronics, Biotech Clean Rooms

- Max Height

- 1200 mm (trolley/bench; varies as per model)

- Frequency

- 50 Hz

- Port Size

- Standardized to clean room fitting sizes (as per design)

- Power Supply

- 230V AC, 50 Hz / Custom on request

- Equipment Type

- Clean Room Ancillaries

- Mounting Type

- Floor / Wall / Ceiling (depending on ancillary type)

- Usage

- Seamless workflow support in cleanroom operations

- Capacity

- Varies by specific ancillary (trolley load, pass box volume, etc.)

- Control Mode

- Manual / Electric (as required)

- Lighting

- LED (in pass boxes/cabinets as required)

- Door Type

- Swing / Sliding (ancillary dependent); interlocked (for pass box)

- Cleanroom Compatibility

- ISO Class 5 to 8 environments

- Compliance

- GMP, CE certifications as applicable

- Surface Finish

- Matt / Glossy SS finish

Clean Room Ancillaries Trade Information

- Minimum Order Quantity

- 500 Square Meters

- Supply Ability

- , , Square Meter

- Delivery Time

- 6-8 Week

About Clean Room Ancillaries

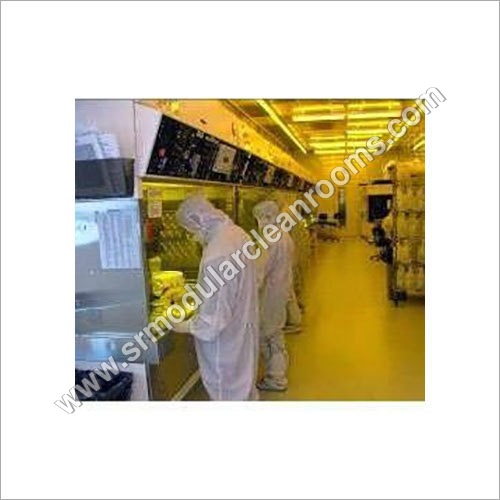

Clean Room Ancillaries

We are engaged in manufacturing of Clean room Ancillaries which are used in various industries like pharmaceuticals. Carefully designed and developed by experts, they are having several attractive and beneficial features like stout structure, attractive designs, fine finish, defects-free structure, minimal maintenance etc. Apart from this, they are made available in different standard as well as customized specifications at market leading rates.

Features:

- Attractive designs

- Fine finish

- Defects-free structure

Seamless Integration for Cleanroom Workflows

Our clean room ancillaries accommodate diverse work processes by offering standardized port sizes, flexible control modes (manual/electric), and mounting options to suit specific cleanroom layouts. Each item is tailored for pharmaceutical, electronics, and biotech environments, ensuring smooth transitions between spaces while upholding strict cleanliness standards.

Quality Assurance & Certification

All equipment is manufactured under stringent GMP guidelines and carries CE certification, affirming compliance with international quality and safety protocols. The matt or glossy stainless-steel finishes provide optimal durability and easy sanitation, essential for maintaining contamination control in high-risk areas.

Advanced Features for Enhanced Usability

Selecting ancillary products with swing or sliding, interlocked doors and high-efficiency LED lighting delivers greater safety and visibility. Temperature resilience from 10C to 45C and customized power supply options further ensure adaptability to operational demands in India or abroad, no matter your cleanrooms requirements.

FAQs of Clean Room Ancillaries:

Q: How do cleanroom ancillaries support ISO Class 5 to 8 compatible operations?

A: Cleanroom ancillaries are specifically designed and manufactured to meet the strict purity requirements of ISO Class 5 to 8 environments, featuring premium surface finishes, sealed construction, and standardized fittings to prevent contamination and ensure seamless workflow.Q: What types of mounting options are available for cleanroom ancillaries?

A: Depending on the model, our cleanroom ancillary equipment can be installed on floors, walls, or ceilings. This flexibility allows optimal use of space and supports various cleanroom configurations across pharmaceutical, electronics, and biotech applications.Q: When should LED lighting be specified in pass boxes or cabinets?

A: LED lighting is integrated into pass boxes or cabinets when visibility and inspection accuracy are essential. This feature is particularly beneficial for critical transfer tasks or quality checks during cleanroom operations.Q: Where are these cleanroom ancillaries typically used?

A: Our ancillaries are widely utilized in pharmaceutical production areas, electronics manufacturing units, and biotech laboratories, wherever stringent contamination control and regulated environments are required.Q: What is the benefit of interlocked swing or sliding doors for pass boxes?

A: Interlocked doors in pass boxes prevent simultaneous opening, thereby minimizing air exchange and contamination risks. This enhances product protection and maintains cleanroom integrity during material transfer processes.Q: How does compliance with GMP and CE certifications impact the process?

A: GMP and CE certifications guarantee that all cleanroom ancillaries are manufactured, installed, and operated according to the highest global standards, supporting regulatory approval and safe, reliable performance.Q: What is the typical operating temperature range and power supply for these ancillaries?

A: The equipment is designed to function efficiently within temperature ranges from 10C to 45C, and operates on a standard 230V AC, 50Hz power supply. Custom options are available upon request to suit unique site requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CleanRoom Ancillaries System Category

Modular Clean Room Ancillaries

Price Range 1800.00 - 2400.00 INR

Minimum Order Quantity : 500 Square Meters

Power Supply : 230V AC, 50 Hz

Test Speed : Variable, up to 300 mm/min

Display Type : Digital LCD

Interface Type : RS485

|

SR PREFABS MODULAR CLEANROOM PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry